Vaughan & Bushnell started offering hand planes to their general tool line sometime before the 1920’s. I have been unable, thus far, to determine an exact date for this but I believe it to be sometime around 1918-1919, though it could be a bit earlier. I do know, however, that absolutely no hand planes appear in the 1914 catalog, so they must have appeared sometime between 1914 and 1921.

It is also unclear whether Vaughan & Bushnall manufactured the entire planes themselves, or bought the rough castings from another manufacturer and machined them in their own factory. However I suspect that there is a good chance that the planes were, in fact, entirely made by V&B from the start.

As far as I can tell, the first range of Vaughan & Bushnell planes were actually called the ‘Vanadium’ series, though these were obviously not the same drop forged series that were introduced later on. These ‘Vanadium’ series planes appeared in the 1921 catalog, but may have also been in catalogs before this time?

The second range of planes were made under the ‘Uncle Sam’ brand. They consisted only of cast iron bench planes from size 3 to 8, though the numbers 2, and 4½ are not noted in the 1922 catalog, or any catalog that I am aware of. Sales were obviously poor for V&B and, as a consequence, these planes are difficult to find nowadays. By late 1922 the ‘Uncle Sam’ series of planes were dropped from the Vaughan & Bushnell lineup in favor of another rebranding.

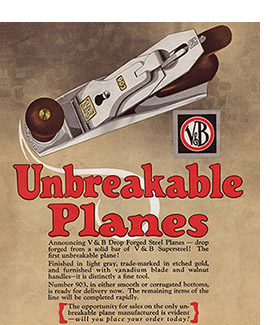

The new range of handplanes was first announced in an advertisement in the National Hardware Magazine of March 1923. The ad stated that “The No. 903 (No. 3 Size) was ready for immediate shipment, and that other sizes would be available soon.”

Like the 1923 advertisement, Vaughan & Bushnell’s own catalogue of 1923 stated that the 903 was available for immediate shipment, with all other planes and sizes available soon.

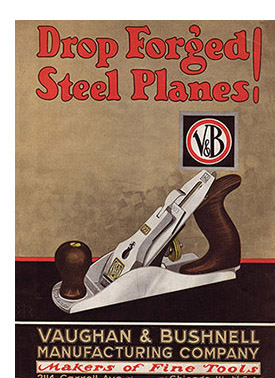

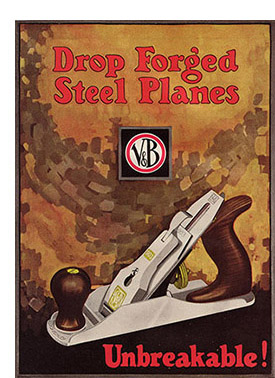

Vaughan & Bushnell’s new method of manufacture was a radical one for planemaking. For 60 years or so the most common method of metal plane manufacture was to cast them from molten iron or gunmetal, or pin them together using dovetails or rods from plates of wrought iron, steel, brass or similar material. The idea of stamping them out from a single red hot billet of steel was simply not a method that anyone had even entertained – until now.

For other plane manufacturers the decision to drop forge the plane bodies, rather than the more common method of pouring molten iron into moulds for casting, would have been beyond all economic rationalization. The monetary outlay for the machinery alone – huge 100+ ton presses for instance – that would be needed to make the bodies in this manner would have been economically prohibitive, especially on the larger models. For Vaughan & Bushnell, however, the decision to do things this way was much more straightforward. Having already invested huge amounts of money in drop presses, brake presses and the like for the manufacturing of the company’s existing, and very profitable, line of hammers, axes, block splitters and similar tools, all that was needed was to machine up the appropriate dies – in itself a reasonably expensive process – heat up the steel billets, ready the tongmen and start stamping out steel planes. Using this technique Vaughan & Bushnell did what they did best. The idea to stamp the planes out was, for the most part, the easiest and most profitable method they knew to make tools, and there would be little or no surprises involved.

The 900 series of ‘Vanadium’ planes were initially a big hit – most likely due to an extensive advertising campaign in both America and Britain. They immediately set themselves apart from other brands partly due to their striking looks and solid design and construction. The mating surface between the frog and the bed of the plane was machined in almost the exact same manner as the, now legendary, ‘Bedrock’ planes produced by Stanley Tools. The Stanley Bedrocks featured a superior design for the frog piece and bed seating, utilising a larger surface area between the mating parts. This meant that the frog was held more solidly in position, thus helping to eliminate chatter. At the time they (the Bedrocks) were considered by many to be the best mass-produced metal handplanes available. Therefore, it would came as no surprise that Vaughan & Bushnell would want to emulate them, then raise the bar again by having a line of ‘unbreakable’ drop forged hand planes.

Finished in light gray with the lever cap logo set in a recessed gold background, the 900 series also came with polished walnut handles and knobs. To top it off, the soles and sides of the planes were plated in nickel. As far as Stanley-type production planes go, they were like no other handplanes seen before. It would be another 14 years until the Millers Falls Company would go one better with their own Number 209 De Luxe Smooth Plane – an absolute beauty featuring chrome sides and sole, with bright red ‘Permaloid’ handles and knobs. Interestingly, Miller’s Falls would go one step further again when they introduced the radically designed 709 and 714 ‘Buck Rogers’ planes in the early 1950’s.

While nowhere near on the scale of more established manufacturers such as Stanley and Sargent, Vaughan & Bushnell’s 900 series planes sold in reasonable enough numbers to keep production going for the next ten years or so, however, the company did have a fallback position as well. Along with the exclusive 900 series of drop forged planes, the company would also introduce a range of cheaper planes in the 1923 catalogue – the 800 series of ‘Lincoln’ cast iron planes. In all likelihood these were probably leftover stock from the ‘Uncle Sam’ series, simply rebranded as the new Lincolns. Like the 900 series, and the ‘Uncle Sam’ range before it, these planes were also modeled on Stanley’s ‘Bedrock’ designs. Thus, by having two lines of bench planes the company would get a better idea of which planes sold and which didn’t.

Being made from cast iron, the ‘Lincoln’ series was available at a lower cost than the ‘Vanadium’ series of bench planes. In fact the cost was less than the previous ‘Uncle Sam’ range that it had replaced. However, the range never had the appeal or popularity that the 900 series ‘Vanadiums’ had. After only a few years, Vaughan & Bushnell dropped all but the two largest sizes of the 800 series. It is believed that these were only kept in the V&B range to compensate for the loss of the 907/c and 908/c planes, which undoubtedly proved to be a little too difficult to manufacture using the drop forge method.

Vaughan & Bushnell also introduced a range of block planes with their 1923 catalogue. These planes were made from cast iron and were, again, modeled on their Stanley counterparts. However, in this case, the decision not to stamp them out from steel must have been a purely economic one. It is much cheaper to make a pattern and mold for pouring cast iron than it is to make a die to stamp out each of the planes that were offered by the company. Like the early ‘Uncle Sam’ series, it is entirely possible that Vaughan & Bushnell did not manufacture any of the block planes at all. Some collectors believe that they may have had the castings made for them by another manufacturer entirely, before machining and finishing them in the V&B workshops. More research is needed by the author in this area to have a better idea of the situation.

There must have been some trouble in producing the two larger sizes of planes, as by 1926 these had been dropped from the 900 range. The amount of power required to effectively stamp out planes of this size may have proven to be too much for the presses that V&B had available.

Around about the same time, Vaughan & Bushnell re-introduced the ‘Uncle Sam’ series back into the tool lineup. This time they were no longer made from cast iron, but stamped out in the same manner as the 900 series of planes. The newly re-introduced range were designated with the 700 series prefix, and came with less finish and plating, along with a cheaper cutting iron. Again they were not quite as popular as the 900 series planes, but they did manage to hold their own until the entire range of V&B planes were dropped in the mid to late 1930’s.

As far as the range of planes offered by Vaughan & Bushnell there are some anomalies. I have not found reference to the Number 2 size planes (Number 2 & Number 902) in any catalog or advertising material, though we know examples exist. All have been of cast iron construction. Likewise, there is no reference made of the Number 4½. Curiously this plane comes in two body styles – a cast iron version, which I believe to be the older type, and a drop forged version. Of the two styles, the drop forged one is marginally more common – however, having said that, it’s a very rare plane with only a handful of examples known to the author. Just when these anomalies were manufactured and sold is unclear – at least for the time being.

Sometime in the early to mid 1930’s, Vaughan & Bushnell added 900 series cutters to the remaindered stocks of 800 series planes, further muddying the waters for collectors. Although these had bodies of cast iron, the planes were apparently still marketed as ‘unbreakable’, however they did come with a replacement guarantee on all defective or broken planes, if necessary.

The exact dates of when Vaughan & Bushnell ceased production of their hand planes is not known, however it is believed that production came to a halt sometime between 1936 and 1938 – and most definitely by the beginning of America entering WW2. The remaining stocks of V&B planes and components (frogs, cutters, bodies etc.) were eventually sold off as surplus, and supposedly used to make planes sold under the ‘Eclipse’ trade name. Some of the bodies are known to have had the ‘Drop Forged’ lettering milled off, and there is some evidence that the same has been done to some of the levercaps in removing the V&B name completely.

Vaughan and Bushnell are still going strong today. Even though they ceased plane making over 75 years ago, they still continue to manufacture a fine range of hammers, axes, pry bars and other tools.